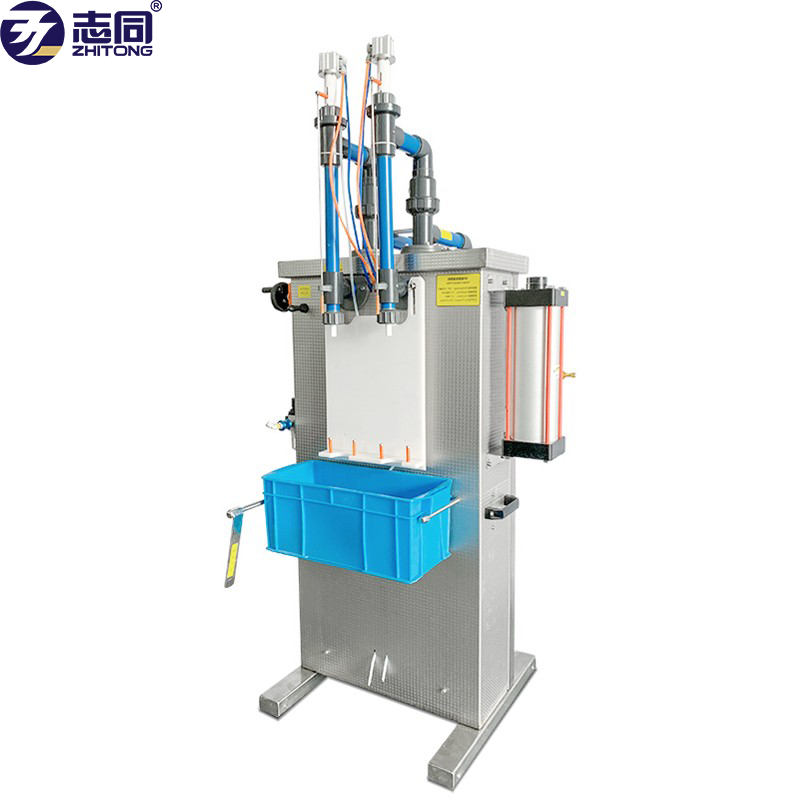

Single Head CE Certificated Water Injection Liquids Alcohol Filling Machine Filler Equipment

Introduction:

Filling machine is divided into semi-auto or automatic type, it can fill liquids and lotions, creams and gels, etc. Different products need different machine, viscosity same products can be filled by one machine.

Based on variety filling speed requirements, machine is optional automatic or semi-automatic type machine. Automatic machine can create high speed, but relatively it takes more space, it can save labour but also more complex. Semi-auto machine speed low but its space required less, one person one machine can save cost for your correspond.

What we mentioned now is the single head water injection filler. It uses a world-class variable frequency speed controller, equipped with importing high-precision multi turn potentiometers and lockable dials, to ensure stable and accurate flow regulation with an error margin of less than 0.5%.

Application: it is suitable for food, medicine, daily chemical and other paste liquid's filling.

Characteristics:

Technical Parameter:

1). Filling Volume: 5-5000ml

2). Capacity: 1800-3600 bot/h

3). Power Supply: 220V/380V

4). Magnetic Pump CV speed change

5). Filling Speed: Adjustable

6). Filling Precision: ≤±1%

7). Working Pressure: Atmospheric Pressure

8). Small pump

Detailed Description of Machine: