Assume full accountability to meet all requires of our purchasers; realize continual advancements by selling the advancement of our customers; grow to be the final permanent cooperative partner of consumers and maximize the interests of clientele for Ordinary Discount Fixed Vacuum Homogenizing Emulsifier for Making Cream, Cosmetic, If needed, welcome to help make speak to with us by our web page or cellular phone consultation, we are going to be delighted to serve you.

Assume full accountability to meet all requires of our purchasers; realize continual advancements by selling the advancement of our customers; grow to be the final permanent cooperative partner of consumers and maximize the interests of clientele for China Mixing Machine and Vacuum Emulsifier Mixer, Our company sets up several departments, including production department, sales department, quality control department and sevice center,etc. only for accomplish the good-quality product to meet customer’s demand, all of our goods have been strictly inspected before shipment. We always think about the question on the side of the customers,because you win,we win!

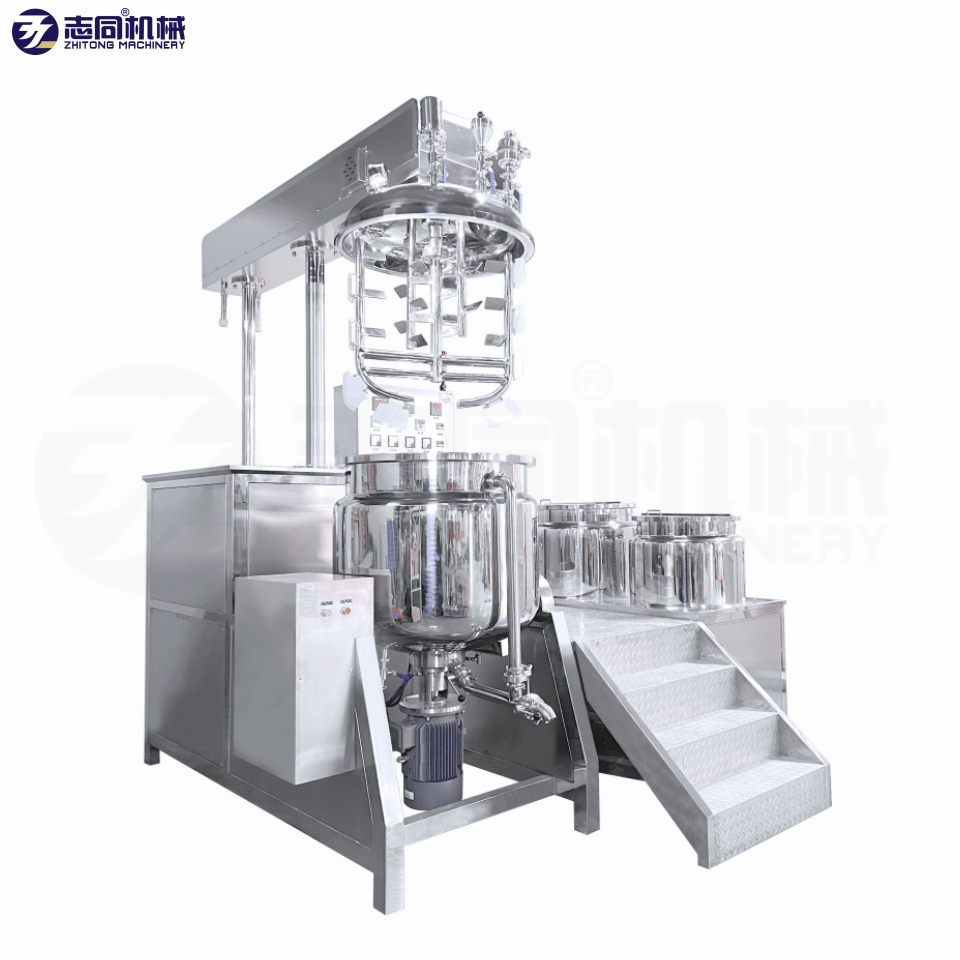

Product Description

1. cosmetic mixer is easy to operate, stable in performance, good in homogenization, high in production efficiency, easy to clean, reasonable in structure, small in area, and high in automation.

2. Internal and external circulation homogenization of cosmetic mixer with higher homogenization efficiency.

3. cosmetic mixer Obtained national practical and appearance patents, national high-tech products;

4. The lid of cosmetic mixer is hydraulic/electric lifting type, and the discharging method is the emulsification pot body is tilted or the bottom is pressurized and the material is discharged with a pump. The best treatment method can be selected according to different products.

5. Homogenizer Emulsifier Mixer with speed vacuum emulsifying mixing equipment with oil pressure lifting system, which can freely lift and lower the boiler and has such functions as boiler tilting.

6. The heat conduction medium in the jacket of Homogenizer Emulsifier Mixer heated by the electric heating tube to realize the heating of the material.

7. The heating temperature can be set arbitrarily and automatically controlled. It can also be heated by steam.

8. The seal of Homogenizer Emulsifier Mixer adopts a specially designed double end face mechanical seal and a secondary seal of the skeleton oil seal, and the mechanical seal adopts cooling water circulating cooling.

9. upper sealing device of Homogenizer Emulsifier Mixer adopts single-end mechanical seal (the sealing liquid adopts glycerin).

10. The dissolving pot is configured according to user requirements for oil and water, and the jacket heating steam valve is manually operated. Electric heating activates the heating button. The upper vertical high-shear homogenizing emulsifier or ordinary mixing device heats feed evenly.

11. The cooling water can be connected to the jacket to cool the material.

15. Homogenizer Emulsifier Mixer Operation Convenient and simple, with an insulation layer outside the mezzanine.

16. The seal of the homogenization device adopts a specially designed double end face mechanical seal and a secondary seal of the skeleton oil seal, and the mechanical seal adopts cooling water circulating cooling.

17. motor speed of Homogenizer Emulsifier Mixer can be controlled by the frequency conversion governor through the frequency conversion speed regulation device to meet the stable speed and powerful torque.

Technical parameter:

|

Model |

Capacity (L) |

Main pot power (kw) |

Oilwaterpot power (kw) |

Hydrauliclift power (kw) |

Total power(kw) |

||||||

|

|

Main tank |

Water tank |

Oil tank |

Mixing motor |

Homogenizer motor |

Mixing RPM |

Homogenizer RPM |

|

|

Steam heating |

Electrical heating |

|

ZT-KB-150 |

150 |

120 |

75 |

1.5 |

2.2–4.0 |

0–63 |

0-3000 |

1.5 |

1.5 |

13 |

30 |

|

ZT-KB-200L |

200 |

170 |

100 |

2.2 |

4.2–5.5 |

1.5 |

1.5 |

15 |

40 |

||

|

ZT-KB-300 |

300 |

240 |

150 |

3.0–4.0 |

4.0–7.5 |

1.7 |

1.7 |

18 |

49 |

||

|

ZT-KB-500 |

500 |

400 |

200 |

3.0–4.0 |

7.5–11 |

2.2 |

2.2 |

24 |

63 |

||

|

ZT-KB-1000 |

1000 |

800 |

400 |

4.0–7.5 |

7.5–11 |

2.2 |

2.2 |

30 |

90 |

||

|

UP TO 3000 |

|

|

|

|

|||||||

|

Remark: The machine dimensioon motor power can be customized according customers workshop |

|||||||||||

Application

Homogenization: medicine emulsion, ointment, cream, facial mask, cream, tissue homogenization, milk product homogenization, juice, printing ink, jam:

(1) Daily chemical and cosmetic industry: skin care cream, shaving cream, shampoo, toothpaste, cold cream, sunscreen, facial cleanser, nutritional honey, detergent, shampoo, etc.

(2) pharmaceutical industry: latex, emulsion, ointment (ointment), oral syrup, etc.

(3) food industry: thick sauce, cheese, oral liquid, baby food, chocolate, boil sugar, etc.

(4) chemical industry: latex, sauce, saponification products, paint, coatings, resins, adhesives, detergents, etc.

Option

Video

Ordinary Discount China Mixing Machine and Vacuum Emulsifier Mixer, Our company sets up several departments, including production department, sales department, quality control department and sevice center,etc. only for accomplish the good-quality product to meet customer’s demand, all of our goods have been strictly inspected before shipment. We always think about the question on the side of the customers,because you win,we win!

-

Professional China Hydraulic Lifting Hand Lotio...

-

China OEM Laboratory Glass Reactor Polymerizati...

-

Excellent quality Emulsifying Cream Making Mach...

-

Top Grade Electric Heating Cosmetics Cream Mixe...

-

Cheapest Price Hygenic Stainless Steel Ointment...

-

Hot sale Factory Mixing Machine Beauty Lotion B...