OEM Factory for Reverse Osmosis Equipment - Reverse Osmosis Industrial System with Edi Unit – ZhiTong Detail:

Video

Product Description

1. RO membrane components are imported products, with high flux, high rejection rate, strong chemical stability and other characteristics;

2. Key electrical components and pneumatic valves are imported to ensure reliable operation.

3. Compared with traditional ion exchange resin system

4. No acid, alkali regeneration, saving a lot of acid, alkali and cleaning water, greatly reducing labor intensity;

5. No waste acid waste lye discharge, is clean production technology, green environmental protection products;

6. The floor area is very small (less than 1/4 of the traditional process);

7.Process easy to realize automatic control;

8.The water quality is good, the water resistivity >17M ω ·cm

9.Reverse osmosis is to desalinate and purify saline by physical method without phase change at room temperature.

10..High degree of automation of reverse osmosis device, little workload of operation and maintenance of equipment.

11. Reverse osmosis pure water treatment equipment adopts automatic control mode to realize automatic operation and reduce the impact of human misoperation on equipment belt.

12. In the pretreatment system, the design of the reduction system is adopted to solve the irreparable impact of excessive residual chlorine on the ro membrane.

13. In the selection of reverse osmosis membrane, the Dow reverse osmosis membrane imported from the United States is selected. The service life can reach 3 years, and the conductivity of effluent water is less than 5us.

14. Lowest water and electricity consumption; Produce pure water to meet the requirements;

15. three automatic working types: programmable control, flow control, peng air system, and set alarm price button

17. high efficiency single stage Z double stage reverse osmosis design

18. .built-in easy to use and easy to install safe and efficient cleaning

19. Low operating costs and maintenance costs.

20. Manual and automatic mode conversion is convenient, with special reminder function to prevent non-operators from misoperation.

21. Water quality correction function, water quality warning function, there will not be a suddenly emergency state.

Technical parameter:

| Model | Capacity(T/H) | Power(KW) | Recovery% | One stage water conductivity | Second water conductivity | EdI water conductivity | Raw water conductivity |

| RO-500 | 0.5 | 0.75 | 55-75 | ≤10 | ≤2-3 | ≤0.5 | ≤300 |

| RO-1000 | 1.0 | 2.2 | 55-75 | ||||

| RO-2000 | 2.0 | 4.0 | 55-75 | ||||

| RO-3000 | 3.0 | 5.5 | 55-75 | ||||

| RO-5000 | 5.0 | 7.5 | 55-75 | ||||

| RO-6000 | 6.0 | 7.5 | 55-75 | ||||

| RO-10000 | 10.0 | 11 | 55-75 | ||||

| RO-20000 | 20.0 | 15 | 55-75 |

Application

1) Pressure is the main driving force of the reverse osmosis separation process. It does not go through the phase change of energy-intensive exchange and has low energy consumption;

(2) Reverse osmosis does not need a lot of precipitant and adsorbent, low operating cost;

(3) The reverse osmosis separation engineering is simple in design and operation and short in construction period;

(4) Reverse osmosis purification efficiency is high, environmental friendly. Therefore, reverse osmosis technology has been widely used in domestic and industrial water treatment, such as seawater and brackish water desalination, medical and industrial water production, pure water and ultrapure water preparation, industrial wastewater treatment, food processing concentration, gas separation, etc..

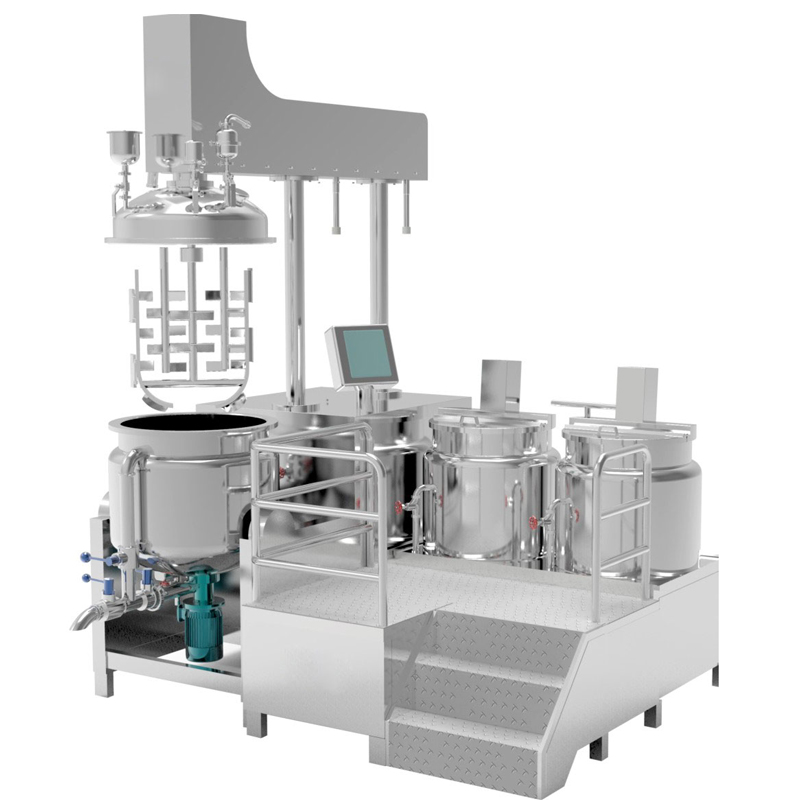

Product detail pictures:

Related Product Guide:

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for OEM Factory for Reverse Osmosis Equipment - Reverse Osmosis Industrial System with Edi Unit – ZhiTong, The product will supply to all over the world, such as: Colombia, Portugal, California, With the technology as the core, develop and produce high-quality products according to the diverse needs of the market. With this concept,the company will continue to develop products with high added values and continuously improve products,and will provide many customers with the best products and services!

A good manufacturers, we have cooperated twice, good quality and good service attitude.