Video

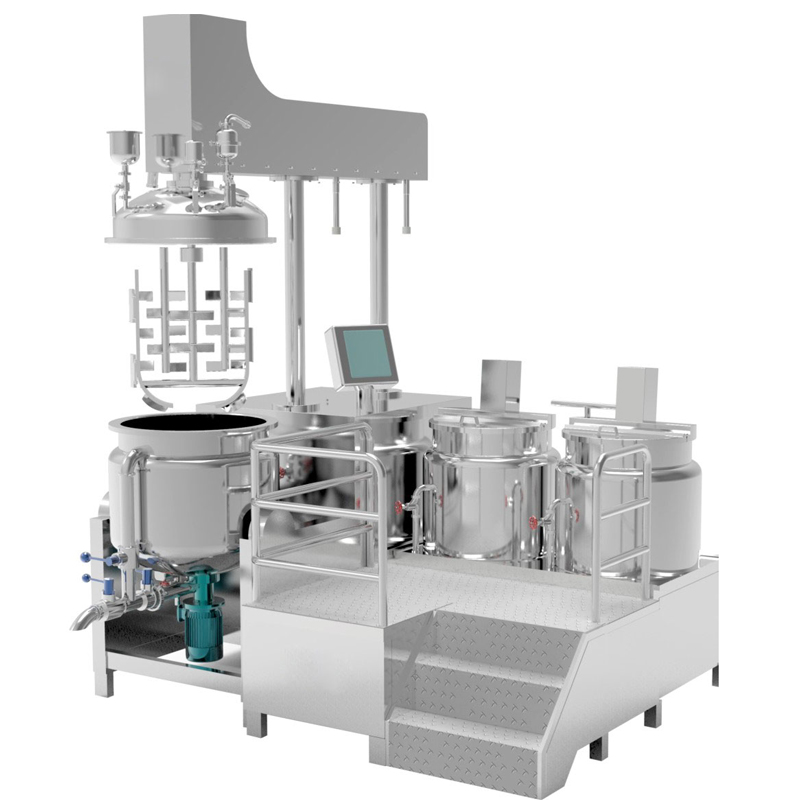

1. Siemens touch PLC operating system

2.tanks material . inner layer SS 316. Middle and out layer SS304

3.Motor brand: AAB OR Siemens

4.Heating method : steam heating or electrical heating or no heating

5.power supply : three phase 220voltage 380voltage 460voltage 50HZ 60HZ for option

6.leader time 30 days

7. Compliance with GMP rules

8.Best cooling way for homongizer mixer High viscosity or no material state will not burn the seal ring

9. The external circulation homogenization system is the core of the system.

10. Water circulation type homogeneous sealing structure, to overcome the common sealing leakage problem;

11. and work under the vacuum state, so that the material can achieve uniform particle size, fine emulsification effect

12. Double direction stirring, clockwise frame scraping wall stirring, counterclockwise slurry stirring, scraper stirrer in operation produce centrifugal effect, make the ptfe scraper close to the wall of the pot, effectively solve the problem of pot wall sticking, leaving no dead Angle,

13.Suitable for the production of salad sauce, Cassida sauce, west point sauce and other medium and high viscosity materials

14. The material in the tank through homogenizing machine's high speed internal channel shear mixing pot for emulsification make sure control oil homogenizing effective

15.efficient system that combines high cycle throughput, uniformity of production material particle size and high efficiency emulsification.

16. According to the material, different heating and cooling devices can be added.

17. Manual or fully automatic machines are also available upon request.

18. completely emulsified and dispersed to avoid agglomeration. In the CIP cleaning process, the system can be used as a transfer pump to provide high pressure cleaning fluid for rotating spray balls.

19. Hydrualic lifting device of emulsifier mixer pot is easier to clean the scraper mixer blender and homogenizer mixer. more safe than pneumatic lifting .

20. pumped to the reactor for agitation, thus avoiding the defects caused by the conventional process.

21. Finished products can be discharged by valve or match a rotor pump. Or positive air pressure..

Technical parameter:

| Model | Capacity(L) | Emulsify motor | Mixing motor | Toal power(steam/electric heating ) | Limited vacuum (Mpa) | Size (mm)L*W*H | ||||

| Main pot | Oil pot | Water pot | KW | RPM | KW | RPM | ||||

| 100 | 100 | 50 | 80 | 4 | 0--3000 | 1.5 | 0-63 | 10/37 | -0.095 | 2385*2600*200-2900 |

| 200 | 200 | 100 | 160 | 5.5 | 2.2 | 12/40 | 2650*3000*2400-3100 | |||

| 500 | 500 | 250 | 400 | 11 | 4 | 18/63 | 3400*3500**3900 | |||

| 1000 | 1000 | 500 | 800 | 15 | 5.5 | 30/90 | 3600*4200*4600 | |||

| 2000 | 2000 | 1000 | 1600 | 18 | 7.5 | 40/120 | 4200*4800*5400 | |||

Option

1.power supply: three phase : 220v 380v .415v. 50HZ 60HZ;

2.Capacity : 100L up to 5000L;

3.Motor brand : ABB. Siemens option;

4.Heating method: Electric heating and steam heating option;

5.control system plc touch screen. Key bottom;

6.Fixed type or Hydraulic lifting type or Pneumatic lifting;

7.variety of paddle designs meet difference requirement;

8.SIP is available upon request for cleaning process.