Mayonnaise Tomato Paste Food Making Vacuum Homogenizing Mixer Blender From Manufacturer

Introduction:

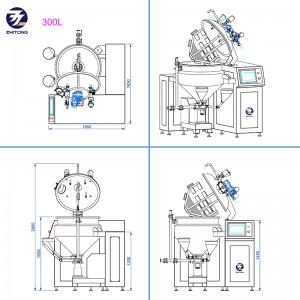

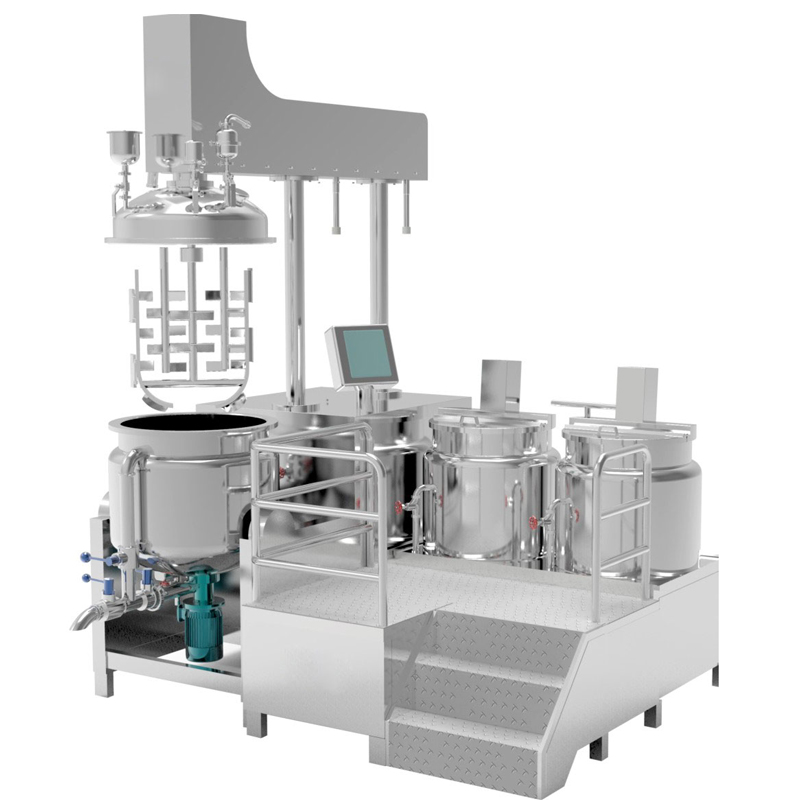

We are manufacturer for mayonnaise, salad dressing emulsifying machine's making over 20 years with factory based on Jiangsu province. Machine main pot cover can be lifting device, cleaning effect is remarkable, the pot body can be incline discharge. The pot body is composed of three layers if stainless steel imported plate welding, the tank body and pipeline are mirror polished, in line with GMP require- ments.

According to the process requirements, the tank can heat and cool the material, heating methods are mainly steam and electric heating 2 methods.

In order to ensure the stability of whole mechanical control, the electrical appliances are imported to meet international standards.

Usage: it is suitable for food and medicine, daily chemical and other paste liquid products' making.

Machine details:

1). Siemens touch screen control cabinet -- neat circuit layout stainless steel control cabinet can monitor the operation of equipment all day and display temperature, stirring speed and other data;

2). Automatic opening --- pull rod open cover, modular design;

3). Valve -- vacuum gauge, vacuum valve, observation hole, essence bucket, suction valve, breathing valve, observation lamp;

4). Main pot --- three layers of stainless steel, plate are welded, tank body and pipe are mirror polished, material lifting device optional, convenient cleaning, cleaning effect is remarkable;

5). CIP cleaning -- equipped with CIP cleaning ball, can be connected with CIP automatic cleaning system;

6). High shear external circulation homogenizer -- product cycle - up and down - multi-layer high shear, the material can be discharged automatically by external circulation, good homogenization effect can reach 0.5μ;

7). Vacuum pump.

Detailed Description of Machine: