Filling principle

The machine is a semi-automatic piston filling machine, which is driven by a cylinder to extract and eject material. The material flow is controlled by a three-way rotary valve. The stroke of the cylinder can be controlled by the reed switch. The filling volume can be adjusted, You can adjust the intake air cylinder to achieve rapid or slow filling.

1.This machine has one pneumatic filling ways, foot and automatic, and they can be switched randomly.

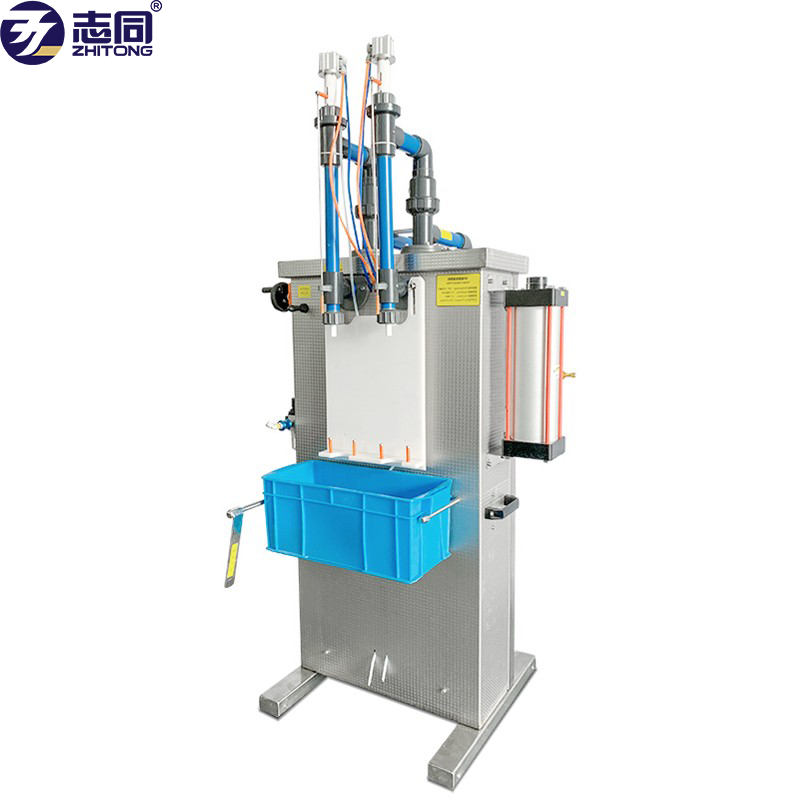

2.The machine is made of full stainless steel ,look beautiful and meets the GMP standard level.

3.Its structure design is reasonable, small size, easy to operate.

4.There are filling volume adjustment handle, filling speed can be adjusted, filling high precision.

5.Filling the valve head can be customized as anti-drip, anti-drawing and lifting filling device. 6.We can accord to customer's requirements to design the filling volume.

7, Be used for filling with particulate matter sauce, paste, liquid and other material;

8, Material contact parts are used 316L stainless steel, the key parts precision processing;

9, Full pneumatic control, easy to operate, remove and clean, ideal equipment for filling inflammable, explosive materials.

10,the machine is made of 304 stainless steel, meeting the GMP requirements.

11,Filling capacity and filling speed can be adjusted.

12,Filling system quick release design, easy to washable after used.

13.Pneumatic components are adopted top-brand pneumatic components.

Technical parameter:

| Model no | Filling capacity (ML) | Filling speed bottle/minute | Pressure supply |

| ZTJ--5 | 5--60 | 1--45 |

0.2—0.6MPA |

| ZTJ-10 | 10--120 | 1--35 | |

| ZTJ-25 | 25--250 | 1--30 | |

| ZTJ-50 | 50--500 | 1--30 | |

| ZTJ-100 | 100-1000 | 1--25 | |

| ZTJ-250 | 250--2500 | 1--18 | |

| ZTJ-500 | 500--5000 | 1--18 |