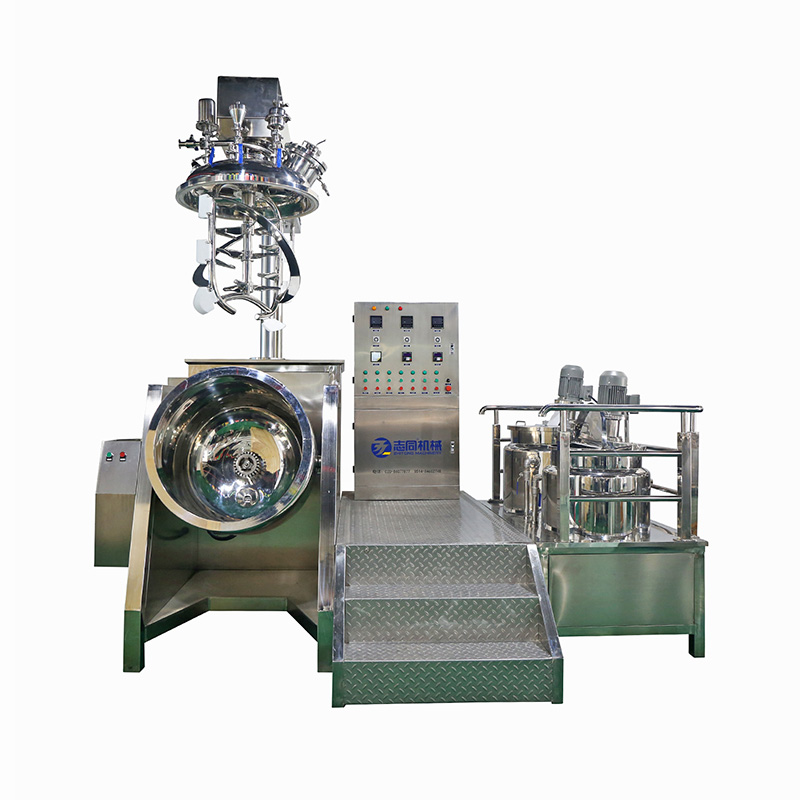

Lowest Price for Soap Mixer Machine - Double hydraulic cylinder emulsion mixer machine – ZhiTong Detail:

Product Description

1. Different jacket designs available for steam and electric heating;

2. Outer anchor agitator has pipe design for enhanced mixing and good appearance; Convenient cleaning.

3. Complex scraping board blending oar is suitable to every kind of complicated recipe and achieve optimizing effect;

4. Suitable for making cream, paste, ointment, lotion, gel, conditioner, milk, sauce, etc.

5. Outer anchor agitator has pipe design for enhanced mixing and good appearance; Convenient cleaning.

6. Different jacket designs available for steam and electric heating;

7. Complex scraping board blending oar is suitable to every kind of complicated recipe and achieve optimizing effect;

8. The vacuum function of this machine can eliminate any germs and bubbles inside the final products;

9. Polytetrafluroethylene scraping board cater to body of blending groove and scrape out viscosity material on boiler wall;

10. Vacuum system to take out the air bubbles during mixing and to transfer the ingredients.

11. Spray ball is equipped to connect customer’s CIP for quickly cleaning.

12. Shorter batch time compared with vacuum emulsifying mixer to save cost.

13. Tilting system for discharging finished product and easy cleaning;

14. The homogenization system adopts German manufacturing technology, uses the gap between the multilayer rotor and the stator to move at high speed, and cooperates with the two-way mixing system;

15. Double temperature probes and controllers for electrical heating in main vacuum homogenizing machine;

16. The downstream vacuum emulsifier adopts advanced electrical control to ensure its stable performance and reliability, etc.

17. Multiple safety protection devices for vacuum, hydraulic pump and workers; All contact parts are made of SS316L and mirror polished.

18.The specifications of the pilot vacuum emulsifying mixer comply with GMP regulations;

19. Exhaust the contents with flatness valve design . there is no resident material in the tank.

20. Cooling system for mechanic seal inside the homogenizer for longer homogenizing time;

21. Diversified types. Homogenization includes upper homogenization, lower homogenization, internal and external circulation homogenization, double, one-way, spiral ribbon mixing, hydraulic lifting and double-cylinder lifting, and multiple options for selection.

Technical parameter:

|

Model |

Capacity (L) |

Main pot power (Kw) |

Oil water pot power (Kw) |

Hydraulic lift power (Kw) |

Total power(kw) |

||||||

|

Main tank |

Water tank |

Oil tank |

Mixing motor |

Homogenizer motor motor |

mixing RPM |

homogenizer RPM |

steam heating |

Electrical heating |

|||

|

ZT-KB-150 |

150 |

120 |

75 |

1.5 |

2.2–4.0 |

0–63 |

0-3000 |

1.5 |

1.5 |

13 |

30 |

|

ZT-KB-200L |

200 |

170 |

100 |

2.2 |

2.2–5.0 |

1.5 |

1.5 |

15 |

40 |

||

|

ZT-KB-300 |

300 |

240 |

150 |

2.5 |

4.0–11 |

1.7 |

1.7 |

18 |

49 |

||

|

ZT-KB-500 |

500 |

400 |

200 |

4 |

5.0–11 |

2.2 |

2.2 |

24 |

63 |

||

|

ZT-KB-1000 |

1000 |

800 |

400 |

5.5 |

7.5–11 |

2.2 |

2.2 |

30 |

90 |

||

|

UP TO 3000 |

|

|

|||||||||

|

Remark: The machine dimensioon motor power can be customized according customers workshop |

|||||||||||

Application

Homogenization: medicine emulsion, ointment, cream, facial mask, cream, tissue homogenization, milk product homogenization, juice, printing ink, jam food industry: chocolate shell, fruit pulp, mustard, slag cake, salad sauce, soft drinks, mango juice, tomato pulp, sugar solution, food essence, additives, etc. 8, nanomaterials: nano calcium carbonate, nano coatings, all kinds of nano material additives, etc.

Option

Product detail pictures:

Related Product Guide:

We have now probably the most innovative production equipment, experienced and qualified engineers and workers, regarded high quality control systems and also a friendly expert income team pre/after-sales support for Lowest Price for Soap Mixer Machine - Double hydraulic cylinder emulsion mixer machine – ZhiTong, The product will supply to all over the world, such as: Norway, New Delhi, Thailand, Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly

-

Factory wholesale High Shear Emulsifier - Pneu...

-

China wholesale Vacuum Homogenizer Cream Mixer ...

-

High definition Industrial Reverse Osmosis Syst...

-

Factory Supply Body Lotion Cream Making Machine...

-

China Water Treatment Plant - Water Treatment ...

-

China Factory for Skincare Manufacturing Equipm...