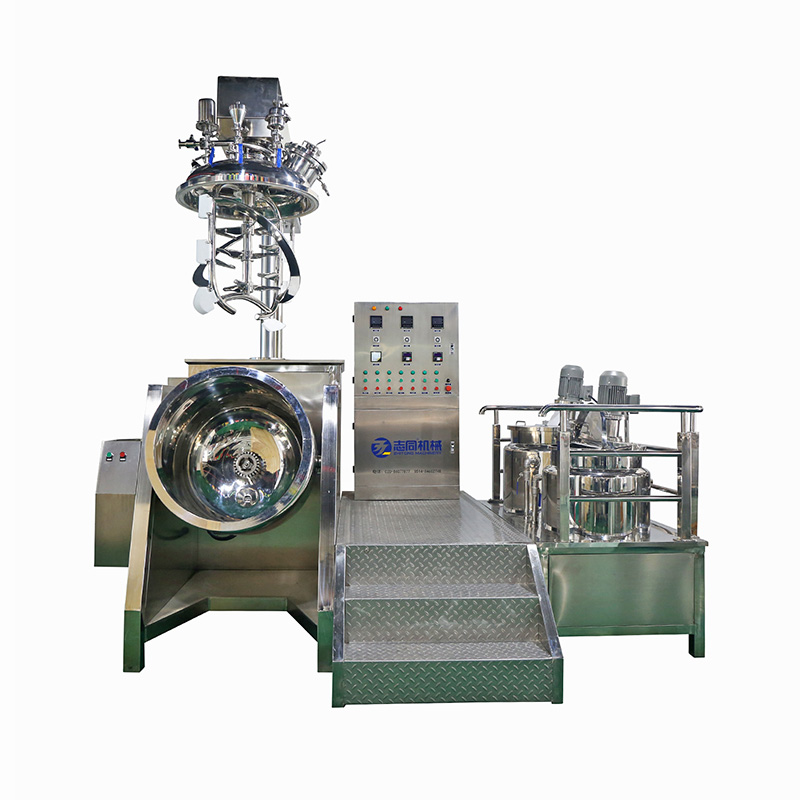

Good User Reputation for Mixing Machine For Cosmetics - Hydraulic lifting type vacuum emulsifier – ZhiTong Detail:

Product Description

1. Lifting emulsifier, including emulsifying pot , operating platform, oil and water pot , oil and water pot and controller; Emulsifying pot device including emulsifying pot, emulsifying pot rack and emulsifying pot cover fixed plate, emulsifying pot set on mixing mechanism, dumping, cooling circulation mechanism, vacuum institutions and emulsifying pot cover lifting mechanism, mixing, dumping, cooling cycle machine, vacuum institutions and emulsifying pot cover the controlled end of the lifting mechanism is connected to the output of the controller.

2. Working capacity from 150L up to 2000L;

3. Suitable for high viscosity material of 10,000~180,000cps viscosity;

4. Homogeneous stirring and paddle stirring can be used separately or at the same time. Material granulation, emulsification, uniform mixing, dispersion, etc. can be completed in a short time.

5. The main pot can be flipped down to 120°so that even the high viscosity material can also be easily emptied.

6. Three-layer homogenizer. Three-layer emulsifying, making fully emulsified and delicate product.

7. Hydraulic lifting system (selected Chinese top1 supplier).

8. The vacuum defoaming can make the materials meet the requirement of being aseptic . The vacuum materials vacuum sucking can avoid dust.

9. Outer anchor agitator has pipe design for enhanced mixing and good appearance.

10.Working capacity from 150L up to 2000L;

11• Suitable for high viscosity material of 10,000~180,000cps viscosity;

12• Homogeneous stirring and paddle stirring can be used separately or at the same time. Material granulation, emulsification, uniform mixing, dispersion, etc. can be completed in a short time

13. Vacuum system to take out the air bubbles during mixing and to transfer the ingredients.

14. Push buttons control panel for easy operation.

15. Oil hydraulic lifting system for easy cleaning and maintenance Double jackets for heating and cooling function.

16. Compressed air to help discharge finished cream save operator.

17. Variable speed for homogenizer and agitator meet difference product quality requirement.

18. the discharge is based on the tilting of the emulsifying tank heating system is electric heating or steam heating that the temperature is automation control set.

19. Outer anchor agitator has pipe design for enhanced mixing and good appearance;

Technical parameter:

|

Model |

Capacity (L) |

Main pot power (kw) |

Oil water pot power (kw) |

Hydraulic lift power (kw) |

Total power(kw) |

||||||

|

Main tank |

Water tank |

Oil tank |

Mixing motor |

Homogenizer motor |

Mixing RPM |

Homogenizer RPM |

Steam heating |

Electrical heating |

|||

|

ZT-KB-150 |

150 |

120 |

75 |

1.5 |

4–9 |

0–63 |

0-3000 |

1.5 |

1.5 |

13 |

30 |

|

ZT-KB-200L |

200 |

170 |

100 |

2.2 |

4.0-11 |

1.5 |

1.5 |

15 |

40 |

||

|

ZT-KB-300 |

300 |

240 |

150 |

2.5 |

4.0–11 |

1.7 |

1.7 |

18 |

49 |

||

|

ZT-KB-500 |

500 |

400 |

200 |

4 |

5.0–11 |

2.2 |

2.2 |

24 |

63 |

||

|

ZT-KB-1000 |

1000 |

800 |

400 |

5.5 |

7.5–11 |

2.2 |

2.2 |

30 |

90 |

||

|

UP TO 3000 |

|||||||||||

|

Remark: The machine dimensioon motor power can be customized according customers workshop |

|||||||||||

Application

Cosmetics, food, medicine, plastic resin, printing and dyeing, printing ink, asphalt and other industries have a wide range of applications.

1, fine chemicals: plastics, fillers, adhesives, resins, silicone oil, sealants, slurry, surfactants, carbon black, defoaming agent, brightener, leather additives, coagulants, etc.

2, petrochemical industry: heavy oil emulsification, diesel oil emulsification, lubricating oil, etc.

3, daily chemical industry: washing powder, concentrated washing powder, liquid detergent, all kinds of cosmetics, skin care products, etc.

Option

Video

Product detail pictures:

Related Product Guide:

We're committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for Good User Reputation for Mixing Machine For Cosmetics - Hydraulic lifting type vacuum emulsifier – ZhiTong, The product will supply to all over the world, such as: Latvia, Madrid, Zurich, Our products are mainly exported to Europe, Africa, America, the Middle East and Southeast Asia and other countries and regions. We have enjoyed a great reputation among our customers for quality products and good services.We would make friends with businessmen from at home and abroad, following the purpose of "Quality First, Reputation First, the Best Services."

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!

-

High Performance Stainless Steel Heating Oil Ta...

-

PriceList for High Speed Dispersion Mixer - Cu...

-

500liter Ro System Water Treatment - Reverse O...

-

Industrial Water Treatment System - Water Reve...

-

Super Lowest Price Small Reverse Osmosis System...

-

Best Price for Liquid Fill Machine - manual lo...