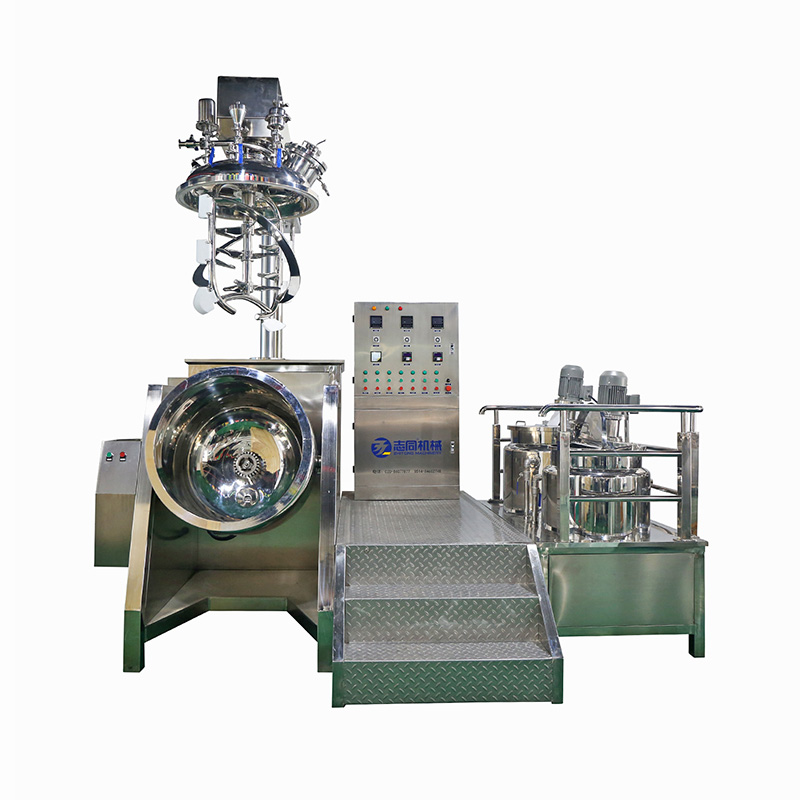

Chinese Professional Ss Tank For Water Storage - Mixing tanks stainless steel jacketed mixing tank with agitator – ZhiTong Detail:

Product Description

1.Polytetrafluroethylene scraping board cater to body of blending groove and scrape out viscosity material on boiler wall;

2.The vacuum cosmetic cream making machine is perfectly suitable for all sorts of cream and lotion production;

3.Complete process of mixing, dispersing, emulsifying, homogenizing, vacuum, heating and cooling in one unit for easy to operate.

4.Vacuum system to take out the air bubbles during mixing and to transfer the ingredients;

5.Polytetrafluroethylene scraping board cater to body of blending groove and scrape out viscosity material on boiler wall;

6.The vacuum cosmetic cream making machine is perfectly suitable for all sorts of cream and lotion production;

7.Complete process of mixing, dispersing, emulsifying, homogenizing, vacuum, heating and cooling in one unit for easy to operate;

8.45 degree inclined blade ,ensures material rolling and stirring effect Seamless welding , easier to clean after production for better machine performance.

9.Adopting the latest technology and the best components from the leading manufacturers.

10.The homogenization system adopts German manufacturing technology, uses the gap between the multilayer rotor and the stator to move at high speed, and cooperates with the two-way mixing system;

11.the material is in a vacuum state during the whole production process, making the material fine and without bubbles.

12.The structure of the vacuum emulsifier adopts concentric double shafts. The agitator and shear of the machine can be operated independently by itself, and the product effect is good.

13.The downstream vacuum emulsifier adopts advanced electrical control to ensure its stable performance and reliability, etc.

14.The downstream vacuum emulsifier adopts advanced electrical control to ensure its stable performance and reliability, etc.

15. Made of imported SUS304 or SUS316L stainless steel. The tank body and pipe are carried out mirror polishing, which is in complete accordance with GMP standard.

16.There are no dead corners inside the vacuum emulsifier, especially those high-viscosity materials are equipped with wall scraper equipment on the mixer.

1.7Cooling system for mechanic seal inside the homogenizer for longer homogenizing time;

18.Diversified types. Homogenization includes upper homogenization, lower homogenization, internal and external circulation homogenization, double, one-way, spiral ribbon mixing,

19. All parts of the emulsifier in contact with the medium are made of stainless steel 316, without any pollution to the product.

20.Teflon scraper, which caters to the shape of the stirring tank at any time, sweeps away the sticky materials on the wall for fast heat transfer.

21.Stepless speed regulation stirring assembly, convenient adjustment of stirring speed at any time, in order to achieve perfect mixing.

Design profile

| Profile | Single layer tank | Double layer tank | Three layer tank |

| Tank material | SS304 or SS316L | ||

| Volume | up to 20T | ||

| Pressure | Vacuum-1Mpa | ||

| Structure | one layer | Inner layer+jacket | inner layer+jacket+insulation |

| Cooling method | No | ice water /cooling water | ice water /cooling water |

| heating method | NO | electric/steam heating | electric/steam heating |

| Agitator type | per customer requirement | ||

| speed 0–63 rpm | |||

| PARTS DETAILS | open manhole / Pressure manhole | ||

| Various types of CIP cleaners | |||

| Sterile respirator | |||

| Inlet and Outlet sanitary valve | |||

| Inlet and Outlet sanitary valve | |||

| 7.Paddle blender .(According to customer requirements) | |||

| 9.Ladder | |||

Technical parameter:

| Model | capacity | Homogenizer motor | Agitator motor | Size MM (D*H*H) |

Limit vacuum (mpa) | ||

| kw | RPM | kw | RPM | ||||

| 1000 | 1000L | 5.5 | 0–3000 | 5 | 0-63 | Φ1000×1200*2200 | -0.09 |

| 2000 | 2000L | 7.5 | 0–3000 | 5 | 0-63 | Φ1200×1500*2500 | -0.09 |

| 3000 | 3000L | 9 | 0–3000 | 7 | 0-63 | Φ1600×1500*2750 | -0.09 |

| 4000 | 4000L | 11 | 0–3000 | 7 | 0-63 | Φ1600×1850*2950 | -0.09 |

| 5000 | 5000L | 14 | 0–3000 | 11 | 0-63 | Φ1800×2000*3300 | -0.09 |

| 6000 | 6000L | 14 | 0–3000 | 11 | 0-63 | Φ1800×2400*3750 | -0.09 |

| 7000 | 7000L | 18.5 | 0–3000 | 11 | 0-63 | Φ4200*4800*5400 | -0.09 |

| Up to 20000 | |||||||

Application

Mixing: syrups, shampoos, detergents, juice concentrates, yogurt, desserts, mixed dairy products, ink, enamel.

Homogenization: medicine emulsion, ointment, cream, facial mask, cream, tissue homogenization, milk product homogenization, juice, printing ink, jam.

Skin care cream, shaving cream, shampoo, toothpaste, cold cream, sunscreen, facial cleanser, nutritional honey, detergent, shampoo, etc.

Option

Video

Product detail pictures:

Related Product Guide:

Our target should be to consolidate and enhance the top quality and service of current goods, in the meantime frequently create new products to satisfy diverse customers' calls for for Chinese Professional Ss Tank For Water Storage - Mixing tanks stainless steel jacketed mixing tank with agitator – ZhiTong, The product will supply to all over the world, such as: Argentina, Sevilla, Juventus, Many years of work experience, we have now realized the importance of providing good quality products and solutions and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.

-

Hot-selling Mayonnaise Emulsifying Mixer - Lab...

-

PriceList for Mayonnaise Making Machine - Hydr...

-

OEM Factory for Industrial Water Purification -...

-

Factory source Vacuum Mixing Machine - Electri...

-

Factory Supply Body Lotion Cream Making Machine...

-

Factory wholesale Soap Mixer Machine - Pneumat...