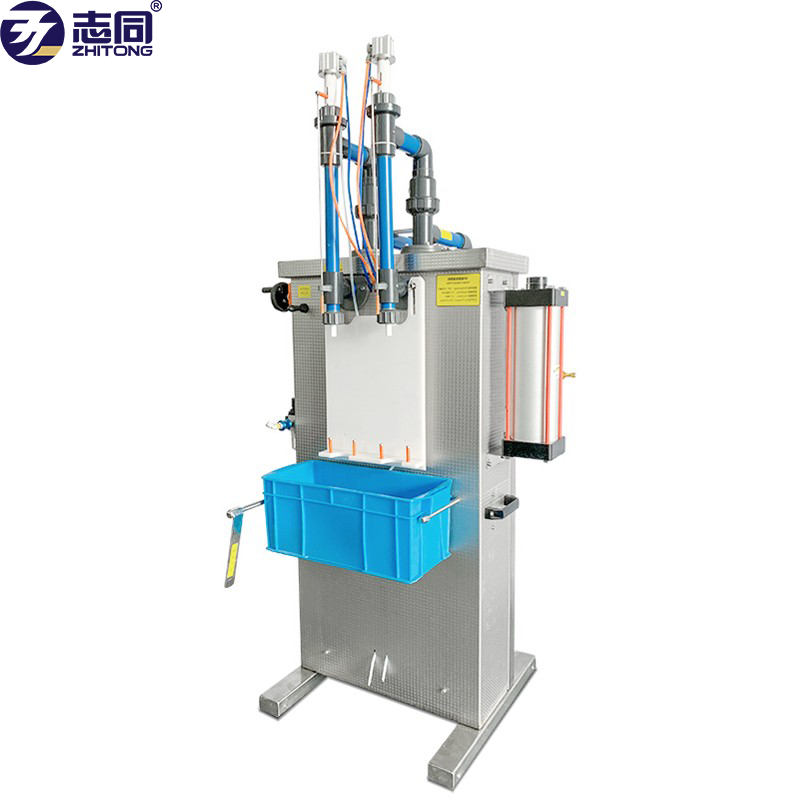

Four (4) Heads Perfume Vacuum Filling Machine Defoaming Filler With Intelligent PLC Controlling

Performance Introduction:

This machine adopts full pneumatic control, especially suitable for filling products with high foam and irregular bottle volume.

The design concept of the vacuum filling machine designed by our company is to apply pressure through the filling head, and the vacuum generator creates a local sealing environment in the return bottle and the bottle to be filled, generating a local vacuum (negative pressure). Filling is achieved through vacuum suction.

Our company can achieve the ideal filling speed and effect through actual debugging according to the customer's bottle type, making it the ideal choice of machine model.

Working Principle:

The working principle of vacuum filling machine (self discharging type) is to connect the air source. Place the bottle to be filled into the mold directly below the filling head and seal it with the filling head. At this point, the cam opens the mechanical valve and closes the vacuum bottle valve and opens the suction valve, causing the vacuum generator to generate vacuum (negative pressure). Create a vacuum environment system (vacuum bottle filling head filling bottle filling head silicone tube). The vacuum suction forces the material into the bottle. When the material inside the bottle rises to the height of the outer sleeve of the filling head. Due to the vacuum suction force passing through the outer tube, the material inside the bottle is sucked into the vacuum bottle to maintain a certain height until the filling bottle is removed. The mechanical valve is closed, and the vacuum generator stops generating vacuum. The suction pipe is closed. The vacuum bottle valve opens, allowing the material inside the vacuum bottle to flow into the barrel due to gravity, completing a filling cycle. The filling amount is filled in units of time.

Application:

It can be used for filling perfume, repellent liquid, essential oils, wine, etc products.

Please note: suitable for glass bottles or hard plastic bottles to fill.

Products suitable for filling: liquid products.

Equipment Parameters:

① Voltage: 220V 50HZ;

② Air source pressure: 0.5-0.8MPa

③ 4 filling heads Size: 700 * 500 * 1600 (mm)

④ Weight: 150KG

Detailed Description of Machine: